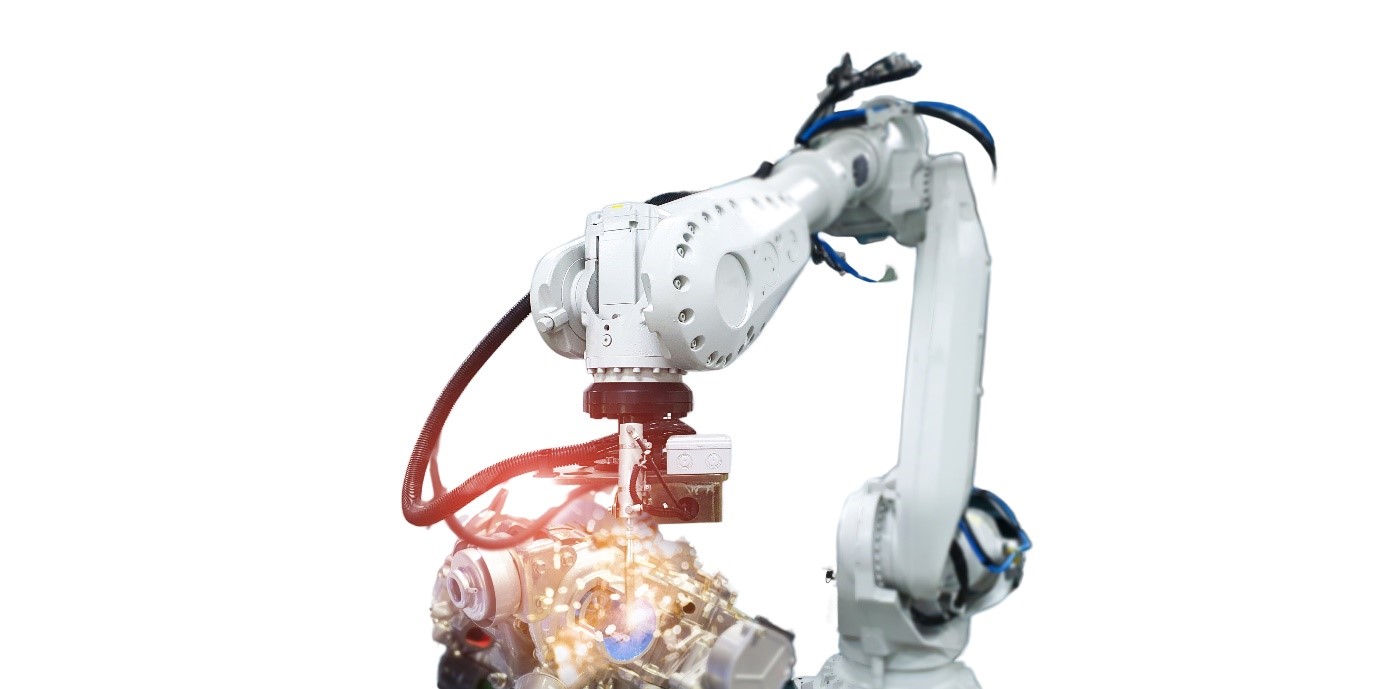

The Power of SMD Harmonic Gearboxes in Industrial Automation

Modern harmonic gearboxes have emerged as the motor of choice when it comes to precision automation for industrial applications. They have become an essential piece of machinery for motion control applications with their high efficiency, improved accuracy, and ability to attain higher speeds. But what exactly is an SMD harmonic gearbox, and how can it benefit an automation system? This article explores the transformative impact of SMD harmonic gearboxes in industrial automation and their unrivalled capabilities.

1. Unmatched Precision and Accuracy:

In industrial automation, precision is crucial, particularly in applications such as robotics, CNC machines, and precision motion control systems. SMD harmonic gearboxes in providing exceptional positional accuracy and repeatability due to their rigid construction and minimal backlash. With gear reduction ratios ranging from 30:1 to 300:1, these gearboxes enable precise motion control with minimal error, resulting in higher-quality products and increased production efficiency.

2. Compactness and Space Efficiency:

Space is often a limiting factor in industrial automation setups, especially when it comes to machinery integration or robotic systems. SMD harmonic gearboxes offer a remarkable advantage in this aspect. Their compact design allows for significant space savings, enabling the development of smaller and more agile machines without compromising performance. By reducing the footprint of automation equipment, manufacturers can maximize factory floor space utilization and optimize overall system design.

3. High Torque Transmission:

SMD harmonic gearboxes are engineered to provide high torque transmission within a small package. Their unique wave generator design allows for efficient torque conversion, making them ideal for applications requiring high torque output. By leveraging this capability, industrial automation systems can handle heavy loads, achieve precise force control, and operate at higher speeds while maintaining stability and reliability.

4. Exceptional Reliability and Durability:

In industrial settings, reliability is paramount to ensure uninterrupted production and minimize downtime. SMD harmonic gearboxes are designed for durability, incorporating robust materials and precise manufacturing techniques. The absence of contacting gears in these gearboxes minimizes wear and tear, reducing the need for frequent maintenance and enhancing overall system reliability. This longevity translates into cost savings, increased operational efficiency, and improved customer satisfaction.

5. Versatility and Customization:

SMD harmonic gearboxes are highly versatile and can be customized to suit various automation applications. Manufacturers can choose from a wide range of sizes, gear ratios, and output configurations to meet specific requirements. This flexibility empowers engineers to optimize system designs, ensuring the best performance for their unique application needs.

SMD harmonic gearbox, a.k.a. a shaft-mounted drive, is an integrated motor and drive that provides accurate motion control capabilities through a combination of mechanical and electronic components. The system works by synchronizing two input frequencies to create a smooth, vibration-free output motion. By controlling the precise timing of these two frequencies, it can deliver torque at varying speeds depending on the gearing.

One of the biggest advantages of using an SMD harmonic gearbox is its ability to generate high torques at low speeds. This makes it the perfect choice for tasks that require constant output speed, such as pick- and-place operations in manufacturing lines or maintaining accuracy for continuous web-printing applications. In these situations, it can help to reduce costs by decreasing power and drive needs.

Another important benefit of using harmonic gearboxes is their increased accuracy and smoother operation when compared to traditional gear systems. When paired with a suitable servo motor, they create a highly precise and rigid system that allows for higher speeds and finer movements. This level of accuracy makes them ideal for applications such as robotic motion control and automated assembly lines.

Their superior efficiency means that they can also be used to improve energy efficiency. By dissipating less heat, their power consumption is significantly reduced, leading to greater cost savings.

In conclusion, an SMD harmonic gearbox is a great choice for industrial automation applications. Its ability to generate high torques at low speeds, improved accuracy, smoother operation, and enhanced energy efficiency make it a valuable addition to any automation system. By leveraging these features, businesses can increase their productivity, reduce operational costs, and take their automation system to the next level.

For More Information on SMD Harmonic Gearbox Download Brochure